-

SIMMTECH Safety Environment Policy

SIMMTECH prioritizes safety and the environment as key aspects of its management and aims for continuous improvement in safety and environmental standards. This safety environment policy applies to all employees of SIMMTECH Co., Ltd., including external stakeholders such as suppliers.

"Safety environment is the first principle of management" and establish standards that exceed legal requirements to create a healthy and safe workplace for all employees.

"Safety environment is the first principle of management" and establish standards that exceed legal requirements to create a healthy and safe workplace for all employees. Continuously improve the level of safety environment through innovative improvement activities by proactively evaluating safety environment aspects and establishing change management procedures.

Continuously improve the level of safety environment through innovative improvement activities by proactively evaluating safety environment aspects and establishing change management procedures. All members, including employees of supplier, implement the safety environment policy to create a safe and comfortable working environment and to identify harmful and dangerous conditions in advance.

All members, including employees of supplier, implement the safety environment policy to create a safe and comfortable working environment and to identify harmful and dangerous conditions in advance. Minimize environmental impact by reviewing and introducing environmentally friendly design, efficient use of resources, and optimal pollution prevention facilities that consider the entire life cycle of products and processes.

Minimize environmental impact by reviewing and introducing environmentally friendly design, efficient use of resources, and optimal pollution prevention facilities that consider the entire life cycle of products and processes. Protect the environment in our operations and communities through systematic management of harmful chemicals and transparent release of information.

Protect the environment in our operations and communities through systematic management of harmful chemicals and transparent release of information.

-

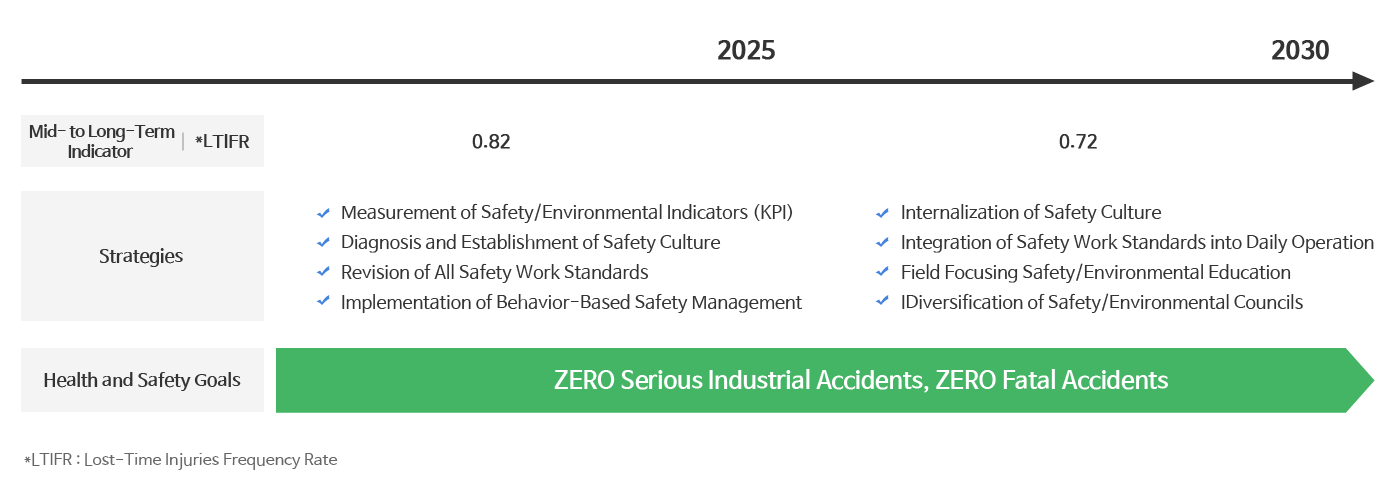

Safety Environment Management Mid- to Long-term Targets and Strategies

SIMMTECH has established a professional and systematic occupational health and safety management system based on the ISO45001 standard. Additionally, based on our internally developed mid- to long-term roadmap, we continuously strengthen the diagnostic and management systems for health and safety elements to ensure that our employees and partner company staff can work in a safer and healthier environment.

-

Occupational Safety and Health Management Activities

Simmtech continuously promotes preventive safety and health activities with the participation of not only its dedicated safety and health department, but also all employees, and partner companies in order to protect workers’ health and maintain a safe working environment. Through the implementation of Process Safety Management (PSM), the company emphasizes safety management and employee engagement, and strengthens workplace safety by conducting activities such as risk assessments and emergency response drills. In addition, various initiatives are carried out to protect the health of employees and to enhance the safety capabilities of partner companies.

-

Enhancing Workplace Safety

Establishing SHE goals

Enhancing Workplace Safety

Establishing SHE goals

Risk assessment

Emergency response drills

Safety and health Training -

Employee Health Management

Investigating musculoskeletal hazards

Employee Health Management

Investigating musculoskeletal hazards

Work environment measurement

Job stress counseling

Occupational healthcare office -

Partner Company Support

Risk assessment

Partner Company Support

Risk assessment

Workplace safety inspections

On-site safety guidance

Safety training

- Industrial Accident Rate

-

(Unit: %)

Year 2023 2024 Industrial Accident Rate 0.16 0.12 LTIFR(Lost-Time Injuries Frequency Rate) 0.78 1.00

-

-

Support for Partner Companies' Safety and Health Improvement

- Regular evaluations are conducted on the safety capabilities of partner companies, and these evaluations are utilized.

-

- Industrial Accident Rate of Partner Companies

-

(Unit: %)

Category 2023 2024 Industrial Accident Rate (%) 0 0

- Through the operation of the Safety and Health Coexistence Cooperation Program, support is provided to ensure partner company workers can work in a safer and more comfortable environment.

-

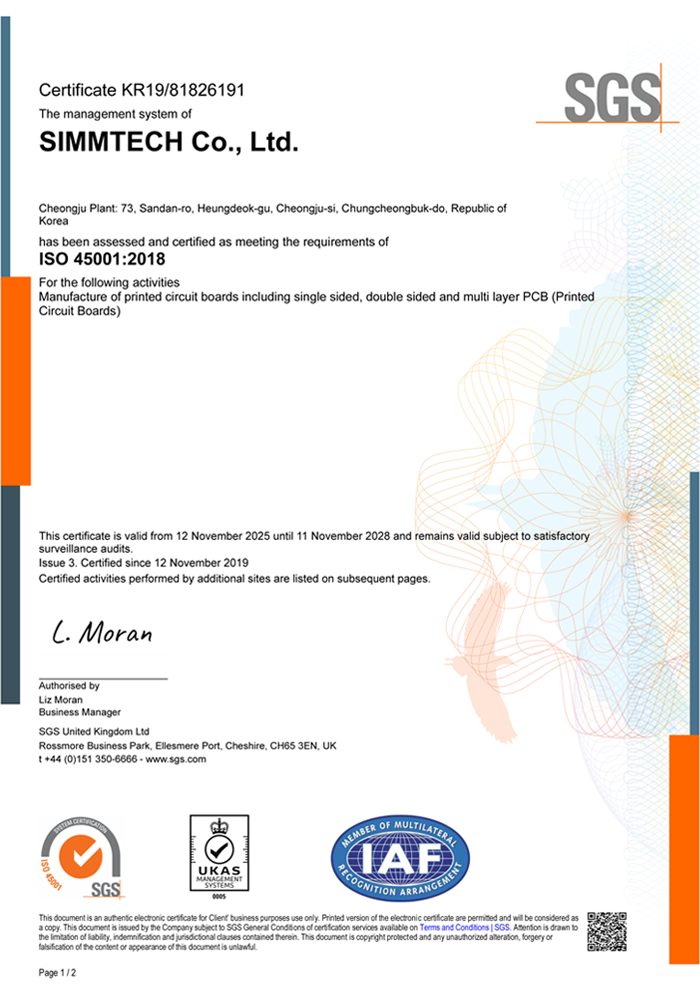

Certification of the Occupational Safety and Health Management System (ISO 45001)

By obtaining ISO 45001 certification, SIMMTECH is establishing an occupational health and safety management system based on international standards.

- ISO 45001 Certification (Validity Period: 2025.11.12 ~ 2028.11.11)

- SIMMTECH International Standard Certification Status (View All)